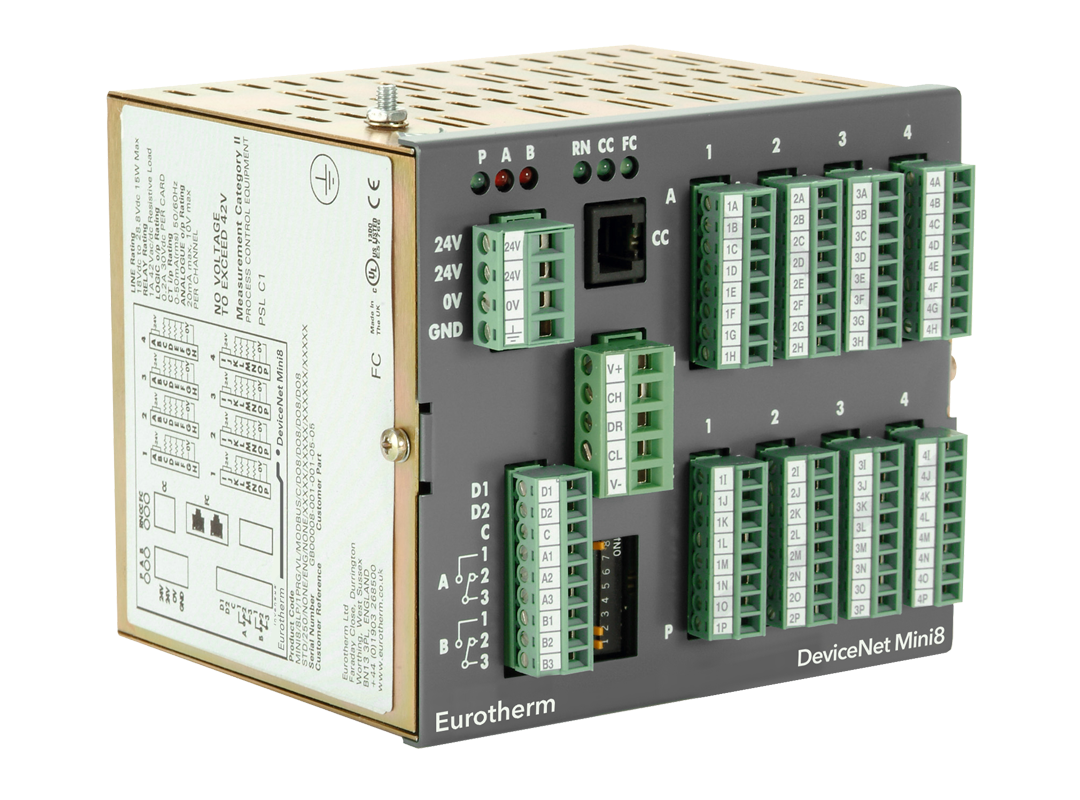

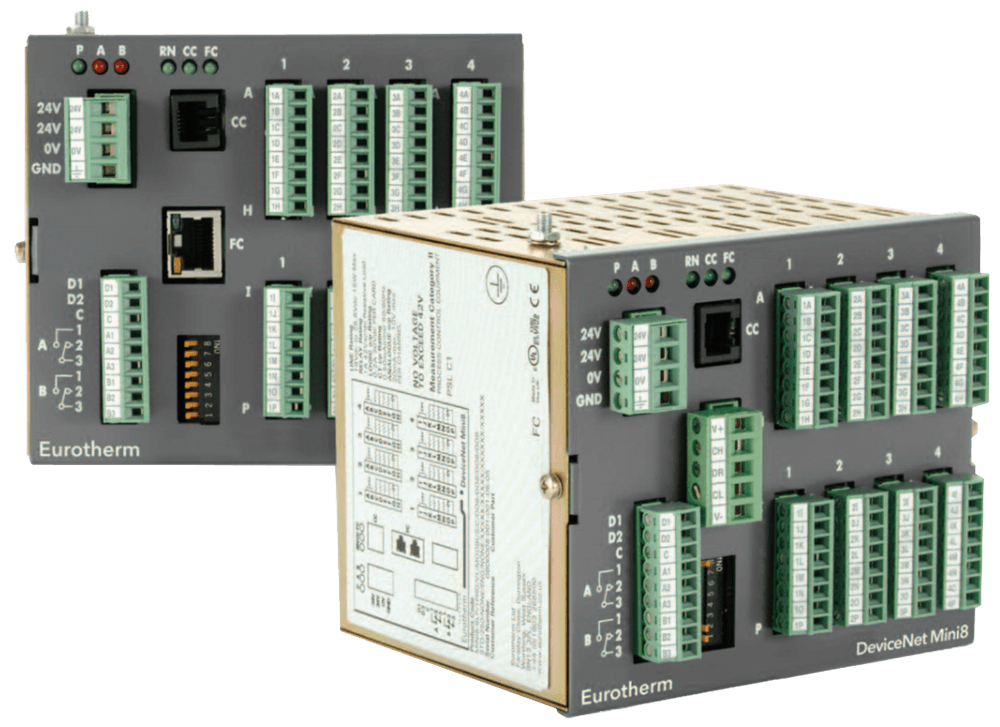

Mini8 Multi-Loop Controller

The Mini8® offers high-performance control usually only found in Eurotherm® panel-mount PID controllers. It is also a very competitive and compact data acquisition device. Its modular design enables its I/O and feature set to be selected to cater for a wide range of applications from simple to complex.

The Mini8 Multi-Loop Controller is an ideal partner to a programmable logic controller (PLC). Able to multi-drop on either serial, Fieldbus or Ethernet communications, it offers a cost-effective alternative to performing analog measurement or loop control in a PLC. Implementing these functions in the Mini8 Controller helps reduce the cost of a PLC system, relieving it of the burden of performing analog functions, often allowing a lower specification processor to be used.

The Mini8’s feature set is comparable with the other Eurotherm Temperature Controllers including its high performance PID control and Setpoint Programmer (SP) programming functions together with a range of features such as Math, Logic, and Timing blocks.

When used in a data acquisition installation the controller’s high density analog I/O can be combined with the Eurotherm 6000 Series paperless graphic recorder.

Benefits:

• Complements your PLC

• World-class control algorithm

• Accurate analog measurement

• Flexible communication options

• Compact modular design

• Reduction in panel real estate

• Can reduce total system costs

Control, Optimize, Simplify

The key features of the Mini8 Controller include:

• 16 control loops

• 32 analog inputs

• Modular & compact

• Setpoint programming

• Math and logic

• Communications protocols

− Modbus RTU

− DeviceNet®

− Profibus DP

− Modbus TCP

− EtherNet/IP

− EtherCAT

• Help defend OEM knowledge and IP with OEM security

Setpoint Programming

The Mini8 Controller can run up to 8 programmer function blocks, to follow a user-defined series of ramp and dwell segments. Each programmer is capable of running a program of up to 16 segments with 8 event outputs. The event outputs can be used internally within the configuration soft wiring or to external digital or relay outputs. (Note: this depends on the type and number of the hardware outputs fitted).

Recipes

Using a PC tool, recipes can be created that can be used to change the operating parameters of the Mini8 Controller simply by selecting a new recipe via a remote HMI. This is very useful where multiple processes use the same controller but require different control parameters.

Heater Failure Detection

The Mini8 Controller with a 3-input current transformer (CT3) card fitted

has the capability of detecting failures in heater loads connected to its time proportioned outputs. By measuring the current flowing through the heaters via 3 current transformer inputs the Mini8 Controller can, for up to 8 loops, detect Partial Load failure, Over Current, as well as SSR short or open circuit. Individual load current parameters indicate the measurement for each heater. The current monitor block utilizes a cyclic algorithm to measure the current flowing through one heater per measurement interval.

Toolkit Blocks

A range of toolkit functions, including Math, Logic, and Timing blocks can be used to create custom solutions and small machine controllers.

Eurotherm iTools Graphical Wiring Editor (GWE)

The GWE is an extremely easy way to create applications. It allows users to select the function blocks they wish to use in their application, then connect them together using ‘Soft Wiring’. The GWE gives the user a pictorial view of exactly what he has configured and can also be used to monitor runtime conditions.