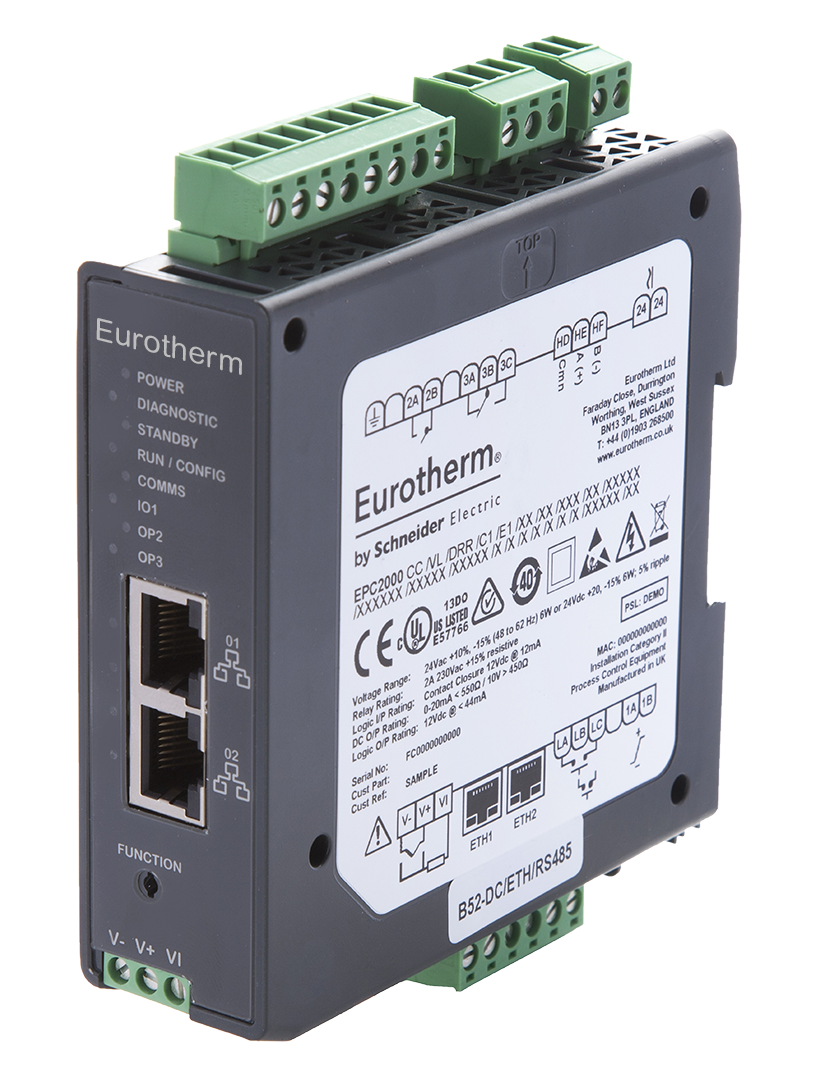

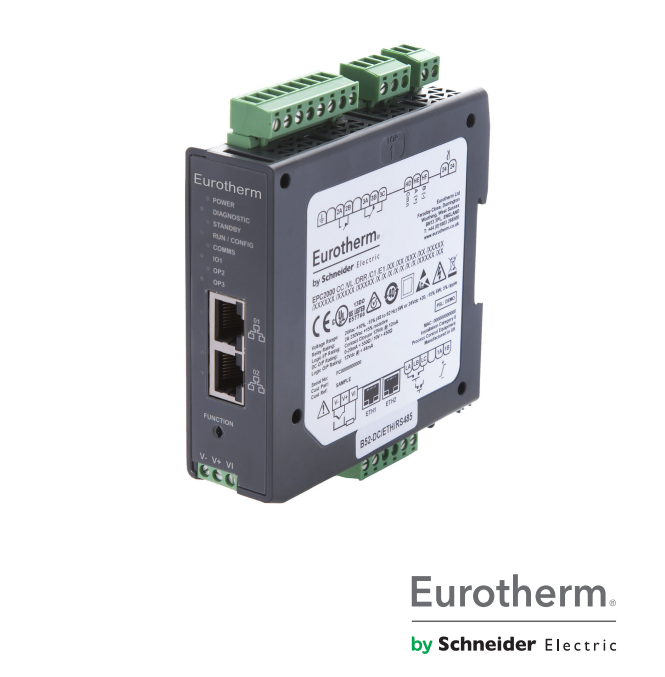

EPC2000 Temperature / Process Controller

The EPC2000 programmable single loop temperature and process controller provides efficient and repeatable precision control in a convenient and easy to deploy DIN rail and surface mounting format. The controller combines precise control and measurement performance with a high-speed Ethernet connection incorporating an integral switch for daisy chain connection to supervisors, panels or PLCs. Cybersecurity is certified to the stringent requirements of Achilles® CRT Level 1.

Key Features Include:

- Precision Single Loop control

- Complements your PLC and/or can be used stand=alone

- Setpoint programming

- Precision analog measurement for repeatable control

- Flexible communication options

- Dual ethernet ports

- EN ISO 13849-1 Performance Level “c”

Controller Function:

Single loop DIN mount PID controller range with autotune, on/off and valve positioning (no slidewire required). Single loop setpoint programmer/profiler up to 10 profiles of 24 segments or 20 profiles of 8 segments. 24V ac/dc options.

PID Control:

Two PID sets are available as standard with separate proportional band for heat and cool. Enhanced auto-tuning control with cutback to minimize overshoot and oscillation. Fast reacting precision control to setpoint changes or after process disturbances. Enhanced valve positioning (unbounded) algorithm. Gain scheduling allows PID selection for a wide range of operating situations, including deviation from setpoint, absolute temperature, output level and others. PV and SP feed-forward functions.

Setpoint Programmer/Profiler:

Maximum 20 program sequences of 8 segments. Options for 1×8, 1×24, 10×24, with textual program and segment names. Holdback (“guaranteed soak”), event outputs, time to target, ramp rate, dwell, step and call segment types. Additional timer functions available.

Additional Functions:

Maximum 20 program sequences of 8 segments. Options for 1×8, 1×24, 10×24, with textual program and segment names. Holdback (“guaranteed soak”), event outputs, time to target, ramp rate, dwell, step and call segment types. Additional timer functions available.